There is plenty of research that demonstrates that projects across industries and geographies struggle to meet the most basic targets.

- Nine out of ten Transport projects

- Six out of ten Energy projects

- Seven out of ten Dams

- Five out of ten technology projects

- and Ten out of ten Olympics

Source: “Why do projects fail?”, Project Magazine, Summer 2015 (http://bit.ly/1QpmN1G)

These do not meet their cost targets. Most strikingly, this trend has been constant with no improvement over the past century.

Examples of Major Project Failures

A good example of a major project failure was the NHS National Programme for IT, also known NPFiT.

NPFIT Failure £10bn

Some of the headlines from the project that hit the newspapers were not good reading.

- The NHS’ huge NPFIT project, intended to serve 40,000 GPs and 300 hospitals

- Most catastrophic IT failure costing £10bn (£3.6bn more than expected)

- Only 13 acute trusts out of 169 received the patient administration systems that were agreed under the National Programme

- The new systems also caused chaos for many users; a newly-installed IT system lost Parts NHS Trust thousands of patient records, delaying the treatment of urgent cases, costing millions in additional staff

- The system of systems that was to provide EHRs was initially designed by a large central team and intended as a complete “big-bang” replacement for the many and varied existing EHR systems

Dyson Electric Car project failure?

The Dyson electric car project was a high profile newsworthy attempt to enter the electric car market by the innovative engineering firm.

- The project got as far as a fully functional vehicle that was near ready for production

- As costs mounted past the £500m mark, the monumental costs of product launch came into view.

- Recognising that to cover the investment and production costs the finished product was likely to have a price higher than the market would bare

- James Dyson funded the costs out of his own pocket

What marks a project failure?

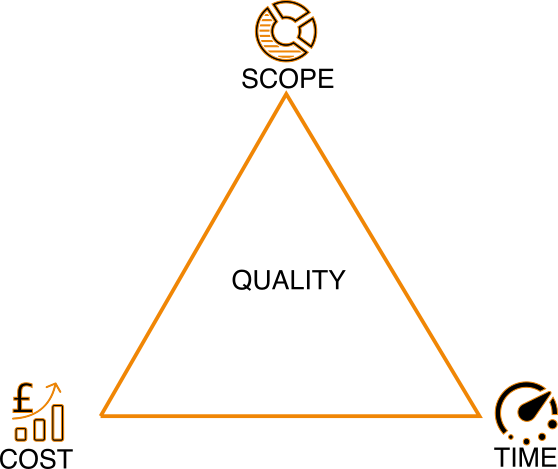

Typically there are three dimensions to project success. These are known as the three constraints, Iron Triangle or project triangle:

- Time – schedule to complete the tasks of the project

- Cost – the budget and financial constraint of the project

- Scope – the tasks required to meet the project’s objectives

Quality is the 4th constraint that exists in the centre of the triangle. Quality focuses on the project’s outputs being fit for purpose.

There was research undertaken by the Oxford Global Group into data on over 12,000 projects:

- Only 47.5% were On-budget (or better)

- Only 7.8% were On-budget and also On-time (or better)

- Of those 0.5% were On-budget and On-time and met their benefits (or better)

For me as a project professional, this is a poor state of affairs but a strong indicator as to how prevalent project failure is.

Recognising Project Failure

Knowing there are key factors that influence project failure is a good start to prevention.

In terms of identifying whether or not your project is going adrift you have to keep your senses alert and be on the lookout for symptoms.

On the Time factor then symptoms could be missed milestones, late deliverables, risks around timelines escalating.

On the cost factor there could be symptoms around a lower spend profile than forecast (something not being done when it should to incur the costs) and then the alternative is a higher spend where unforeseen costs appear.

With the scope factor you could face additional activities coming into scope that were previously unknown.

Managing the symptoms early will ensure the project can course correct before significant harm is done.

You can read up on how to address the symptoms of project failure starting the series with the article here.